Posts

2

minutes

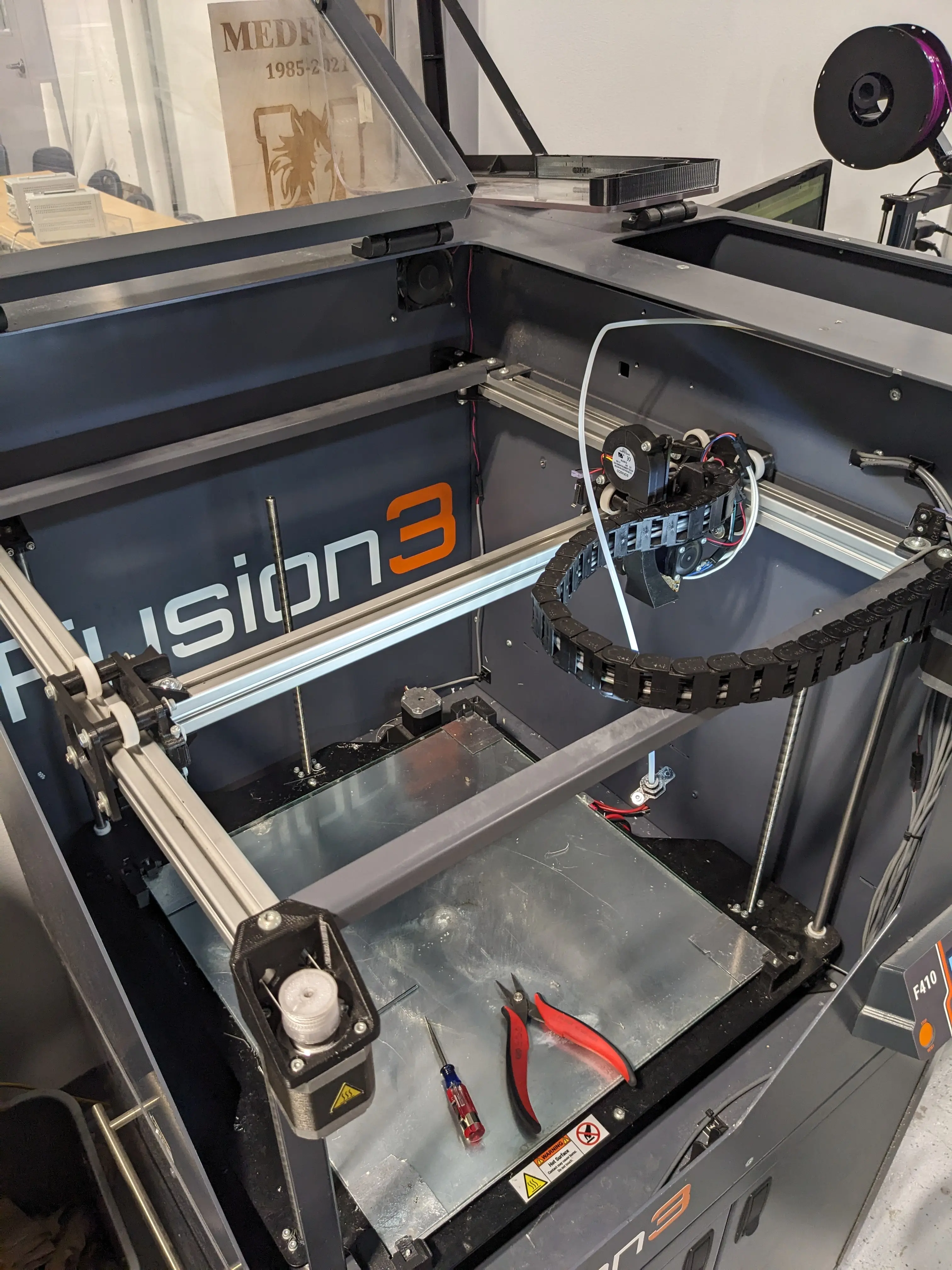

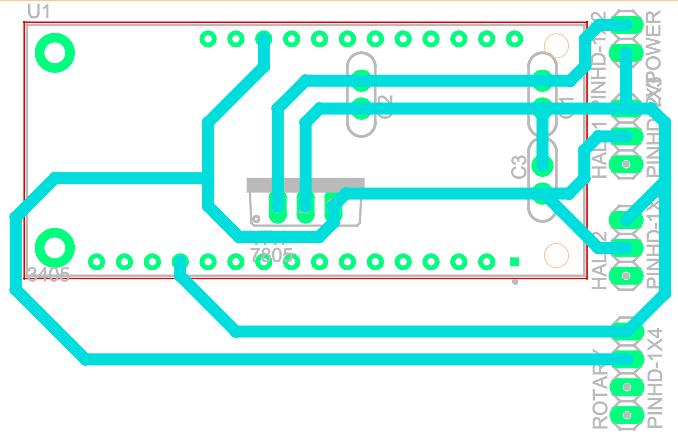

This week, I continued working on the Sumo Bot project. I re-printed the frame and milled another PCB, then soldered all the components together. We will be making two robots for the competition. Likely, the bot will be ready to test and debug early next week.

Although in the process of printing, I noticed that one of the Fusion 3s wasn’t working. Will graciously fixed the jammed extruder on the printer, but it was still having unexpected difficulty when homing the Y axis.

2

minutes

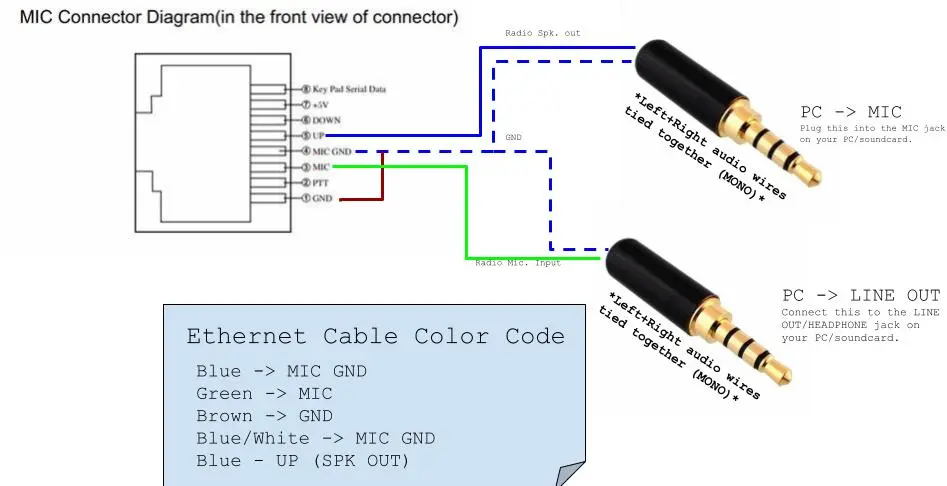

Introduction Today, I will walk you through the creation of a cable for your Anytone AT778 or Retevis RT95 ham radio, enabling you to both send and receive digital modes. This post is very similar to my old one, where I made a digital audio cable for the Baofeng UV5R. Check that out if you have a UV5R. If you want custom cable instructions, feel free to ask.

This cable will allow you to both RX and TX any digital mode from your laptop, including (but not limited to)…

1

minute

This week, I made a major software breakthrough on the ROV.

The IMU will periodically return invalid data, likely due to a faulty sensor. Due to the lack of error handling in the code, the ROV would receive a null value and the enire software system responsible for the control of the ROV would crash and need to be restarted. This bug that I’ve been tracking for nearly a month now was resolved by simply implenting some basic catches to detect when these null bits come in, and simply ignore them.

1

minute

This week, Tim finished his electronics skeleton that he has been working on for the past few weeks. It looks very nice and is completely custom designed, machined, and resin printed. I helped him install it into the ROV, and I can already tell that it will make things significantly easier in terms of debugging and also performance of the overall machine.

The previous layout consisted of floppy acrylic fingers that held the PCBs in place.

2

minutes

Over the weekend, two of my friends and I went out foxhunting. On the groups.io page, we found a few local foxes that had been set up. We took the opportunity to drive 30 minutes North to see what we could find!

Since we all got our radio licenses around the same time, we all purchased the same, budget-friendly HT: the Baofeng UV-5R. We brought along for with us for the endeavor, and an assortment of various antennas- from long whips to little stubbies.

2

minutes

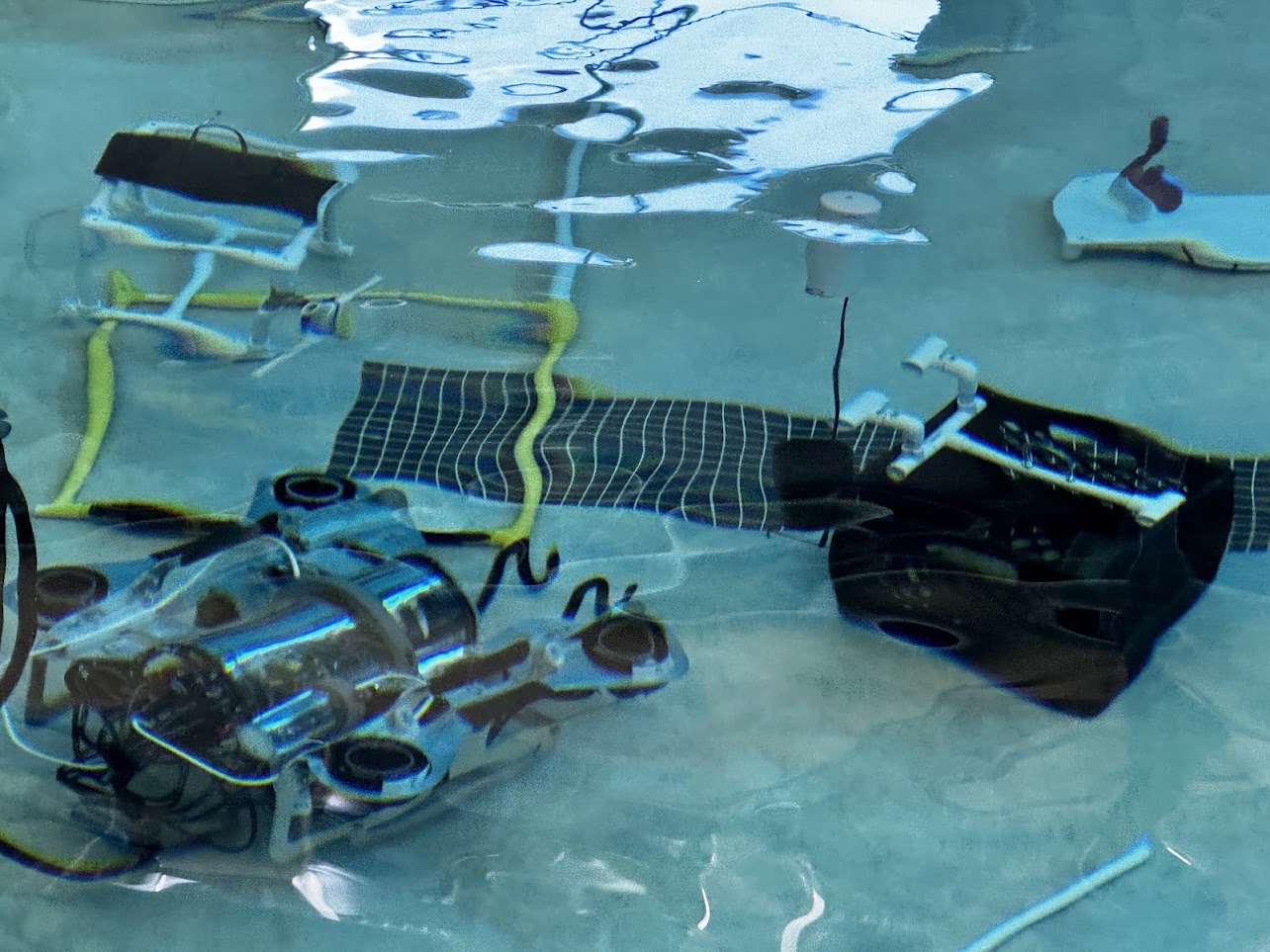

The first 2 days of shop this week were spent replacing XT30 connectors on the ROV’s power distribution board. There have been connection issues in the past, and I really didn’t want this to factor into existing reliability issues.

On Wednesday, Jonas Wirz and I got the ROV into the pool, however, we had some free time before then and were very productive with it.

Short-lived gated off area exploration (right).

3

minutes

When I bought an upgrade from my baofeng UV5R (ANYTONE AT-778UV), I figured a new antenna set-up was in store.

My base station antenna is a Diamond X50, attached to a custom mast.

This setup was a heck of a lot better than the rubber duck on my handheld, but because it was only about 8ft. from the ground, the environment and houses nearby would block both TX and RX signals significantly.

5

minutes

This week I locked in and spent a good chunk of time identifying the reasoning behind the mysterious crashing phenomenon we have been experiencing for over a year and a half in the ROV.

Raspberry Pi 5 Problems In the past, the main control computer (RPi 5) was experiencing power interruption issues due to the massive current draw of the 8 thrusters. Because of the low dropout voltage in the 5 volt regulator, we found that adding some capacitange along these output lines helped smooth out any wild ripples.

4

minutes

This week was a bit funky. Not only did I have limited time in shop, but limited time in school overall!

Our school had a half-day on Wednesday (we get released at noon) and the day after was a snow day.

Because of these two things, I didn’t have a whole lot of time to work on roboticy things.

This is enough to call a snow day?! Nonetheless, my friends and I ended up getting some work done on the ROV on the days we did have.

3

minutes

This week consisted of a combination of activities both during shop-time and during robotics club. I spent the majority of my shop time helping my classmates with their light boxes. This included anything from crimping connectors to soldering small parts onto PCBs. I also spent some time optimizing the ROV in terms of performance and reliability, which included setting up a systemd service to automatically start the main ROV software.

3

minutes

This week, I worked on the ROV for the robotics team as I had already completed the lightbox project as shown in the previous post. The robot has been experiencing some reliability issues, and they have something to do with the Raspberry Pi 5 we have onboard. The Pi would suddenly “crash” (meaning a loss of connection over ssh; ethernet port lights turned off; only red power light was illuminated) without warning.

3

minutes

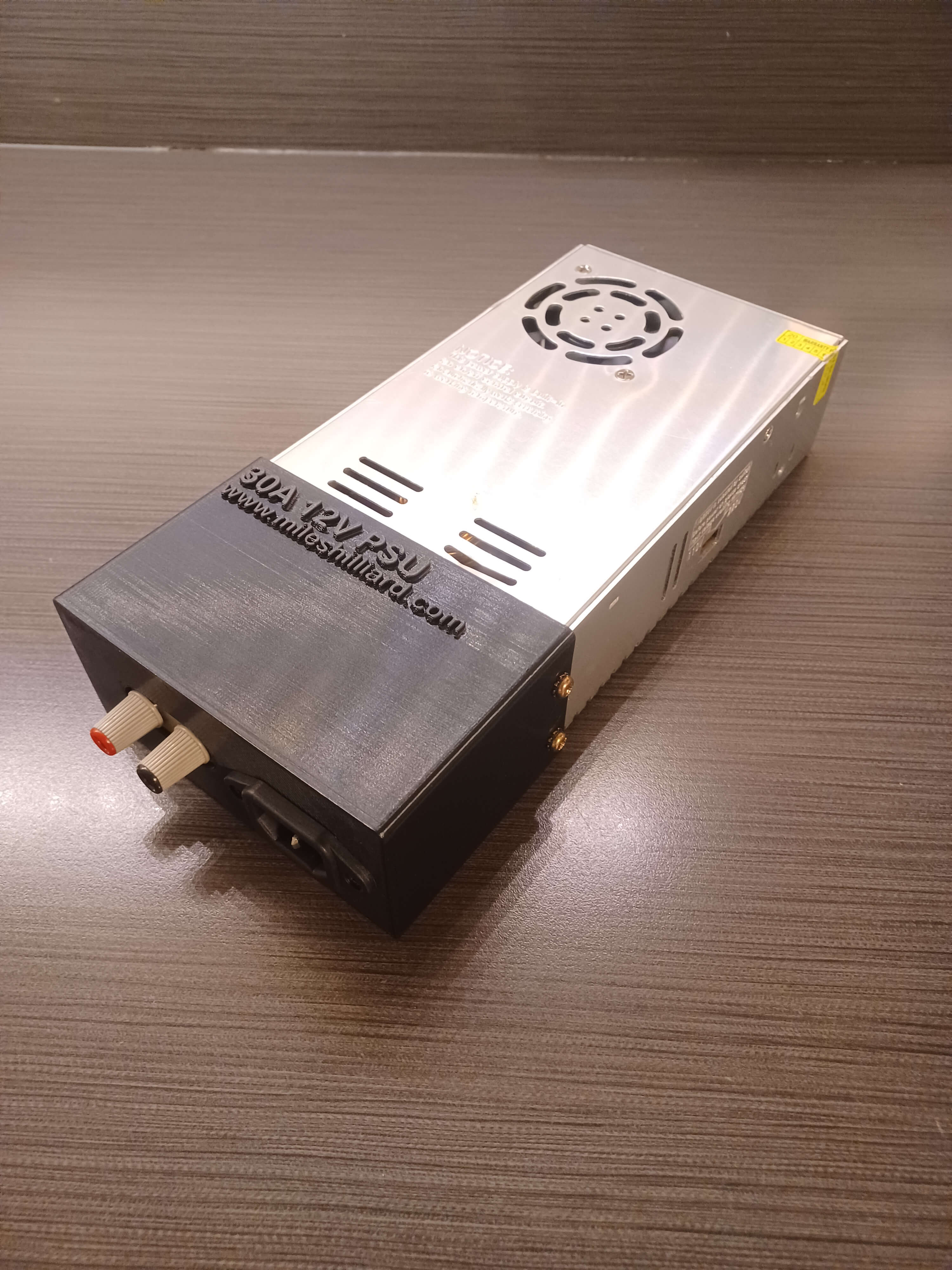

I have had this cheap 12V switching power supply that (claims) to be able to deliver 30 amps. It is a common power supply type, and are commonly used in consumer applications, especially in the LED lighting industry. In fact, the exact same model can be found mounted on my Creality Ender 3 3D printer.

Background Personally, I find these power supplies perfect for many use cases, especially when one considers their pricepoint.

1

minute

The lightbox has been finished! I designed the acrylic and manufactured it on our laser engraver/cutter. The end result was better than expected, although I had to condense (shorten) the acrylic overall to meet the max acrylic dimensions of 70 square cm.

After the transparent acrylic was finished, I screwed it into the lightbox and “force fit” everything together as designed. Luckily my tolerances and dimensions matched perfectly.

The acrylic had to be custom designed to fit the screw holes and the box geometry.

2

minutes

While in robotics this week, I continued my work on the lightbox project. This week involved a lot of CAD and 3D printing for me, and ended up taking a bit more time than expected. Generally speaking, I am ahead of schedule so I don’t have to worry too much.

The light box is composed of two main parts that get 3D printed and screwed together. There is the base which is the outer shell and holds the button and power jack.

2

minutes

SSH is awesome, but your options when trying to run a GUI application are a bit limited, especially on headless computers. Luckily there are a few ways to go about handling this problem, even if your computer has no monitor directly connected to it.

SSH into the machine First of all, you need to ssh into your machine to get everything set up. Now you have a couple options. Some people may have a display (be it a full monitor, a TV screen, a touch display, etc) and others may have nothing it all.

2

minutes

Paper bags are great. They are much more sustainable than their plastic counterparts and they are reusable and recyclable. I often keep or collect these bags because they have so many uses.

The issue I have is that I don’t have a good place to put them. At the moment, they are stored behind my recycling bin, being propped up. When I take out the recycling they all fall down and make a mess.